OHFS Machine- Open Hold Fill Seal Machine for Preformed Pouch

Shruti Flexpack provide many products related to packaging. All products of Shruti Flexipack are best in the packaging industry and form that VFFS with Multihead Weigher machine is one of them.

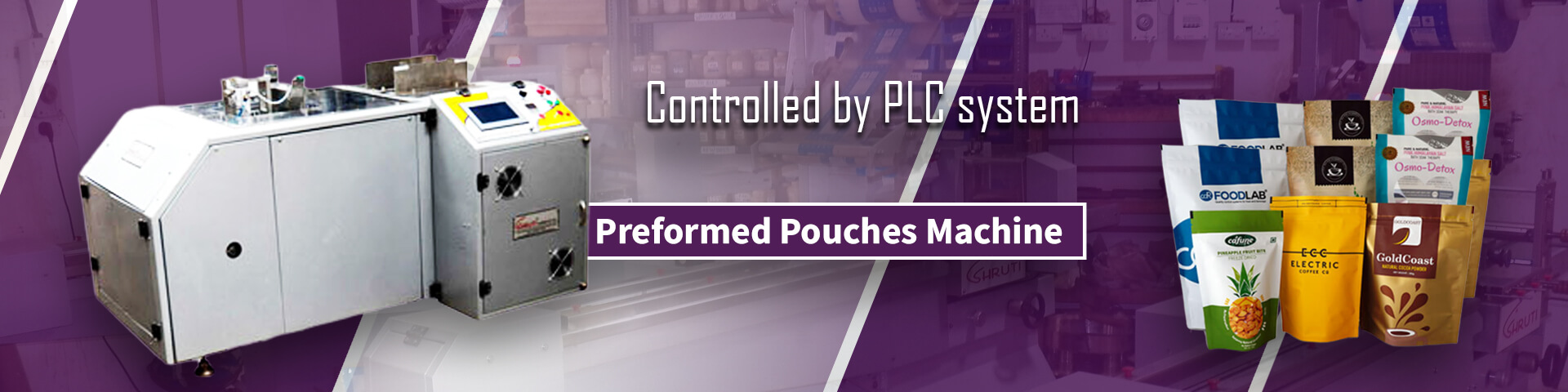

This pouch packing machines is equipped with latest design PLC, control and multicolor HMI. For various timing of machine, all parameters can be set from the HMI. This Pouch Filling Machine packs number of pouches in one minute and production in a day will be displayed on the screen.

Products can be fed to the machine by using various options such as manual hopper, cup filler for granular products, auger filler for powder products, weigh filler, auto conveyor, bucket conveyor, piston filler for liquids, etc.

This pouch packing machine operates fully compressed air and is controlled by PLC system. This machine can be operated with minimum labor and requires minimum maintenance.

| Formats of pouches | Stand up pouches, preformed center seal or side sealed pouches, Quadra seal pouches, zipper pouches, box type pouches, magic sealed pouches etc. |

| Output | 4000 to 5000 packs per day |

| Fill Weight | Standard model is up to 2 Kilogram |

| Pouch Width | Minimum 150 mm to maximum 300 mm with change parts |

| Pouch Length | 200 mm to 350 mm |

| Packing material | Any heat sealable laminated film made preformed pouches such as polyester poly / paper poly/ metalized poly/ Aluminum foil. |

| Bag Loading | Adjustable cartridge or magazine will be provided to feed up to 300 pouches Preformed bags can be loaded while the machine will be in operation. |

| Bag Opening | Adjustable vacuum bag opening assemble will be fitted. |

| Wastage | To avoid spillage no bag no dump mechanism will be available. |

| Opening and filling | Individual bag will be removed from cartridge area and rotated, then opened below the feeding area Special designed pneumatic and suction mechanism will be provided for this operation. |

| Product Feeding Chute | In case of difficult products; feeding chute will having up and down action to avoid product spillage and to avoid the seal area contamination, this will ensure leak-proof sealing. |

| Pouch holding | During filling of product for packing, pouch will be held by specially designed grippers, which hold the pouch in proper opened position during filling of product. |

| Pouch Sealing | Continuous heat sealing bars will be fitted to seal the pouch, heating will be controlled with digitally displayed PID temperature controller. |

| Preformed Pouch Packing Machine control | Complete machine is controlled by available best Programmable Logic Control and HMI of reputed manufacturer State of art programming will minimize downtime of machine. |

| Product examples | Coffee beans, pet food, sea food, sugar, flour, frozen food, liquids, pastes, candy snacks, coffee, tea, food products, pet sticks, solid products, chemicals, hardware, uneven shaped products and many more. |

| Optional arrangements | Gas flushing, name embossing, special pouch sealers, inkjet printer etc. |

| Air requirement | 275 liter per minute at 6 Kg per square centimeter. |

| Power supply | 440 volt, 3 phase with neutral and earthing. |

| Net Weight of the machine | 450 Kg. approx. |

| Overall dimensions approx. | Length- 2100 mm Width- 800 mm Height- 1550 mm. |

Shruti Plexipack is a Pouch Filling Machine manufacturer and supplier in Navi Mumbai, India. We have Preformed Pouches Machines which is also known as pizza packaging machine, burger packing machine, masala pouch packing machine, fruit pouch maker, etc. Contact us for more details.